Coal-burning power plants

Elements of all systems of thermal power plants are subject to wear. Particularly, this applies to coal and ash storing and transporting systems: equipment for coal grinding, coal dust feeding to the boiler burner, dust collection, removing ash, fly ash and wet ash. Similar problems arise with the equipment for feeding limestone and gypsum in desulfurization systems.

The following materials are often used to ensure many years of trouble-free operation:

- fused cast basalt

- wear-resistant ceramics

- hard wear-resistant compound

- hardfaced wear plates

In addition, various combinations of the above materials are successfully used in various applications, which allows operators to obtain optimal technical and economic results.

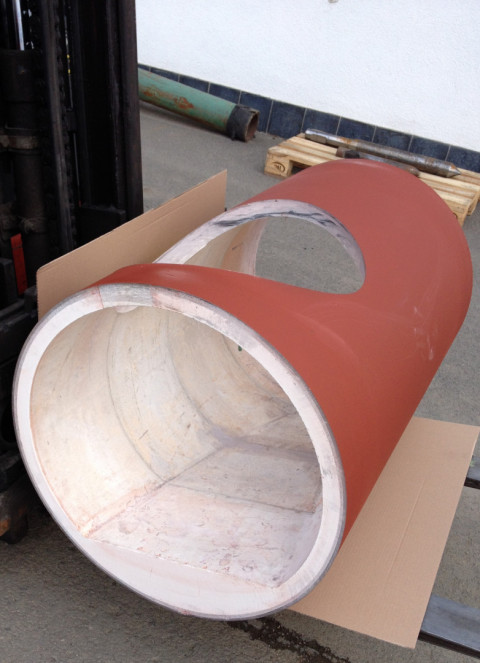

Fused cast basalt has proven to be excellent for protecting ash and slag pipelines of thermal power plants. Pipes for wet ash transportation are usually coated with fused basalt in numerous countries. This material is time-tested and combines high wear resistance and excellent corrosion protection. The service life of ash and slag pipelines lined with fused basalt rings is more than 20 years. No material in this price range has such a long service life.

WEARTECH accumulated vast experience in supplying pipes lined with basalt for transportation of abrasive materials of various configurations, with an inner diameter of 40 mm to 2500 mm. Steel casings (pipes) can also be effectively protected against corrosion.

Pipe connection can be flanged or welded.

WEARTECH also supplies a wide range of wear protection products made from ceramic and hard metallic materials, as well as wear- and chemical-resistant compounds.

The conveyor and storage systems of coal-fired power plants handle large quantities of bulk materials. Without proper protection, these systems often fail and require repair or replacement. Material movement inside bins and silos must not be allowed to stop. WEARTECH delivers tailor-made solutions for specific applications using a wide variety of materials, including wear resistant compounds, hard metals and ceramics. Our experts are ready to provide you with the necessary assistance.

Advantages of lining materials

Ceramic wear protection

- highly effective protection against abrasive wear;

- lining in the form of tiles, cylindrical or seamless elements;

- temperature resistance up to 1000 °C.

Metal wear protection

- highly effective protection against wear under sliding and shock loads;

- thin walls and autonomous load-bearing structures;

- good resistance to sudden temperature drops.

Combination of different materials

- optimum wear protection in all applications;

- protection cost optimization;

- weight optimization.