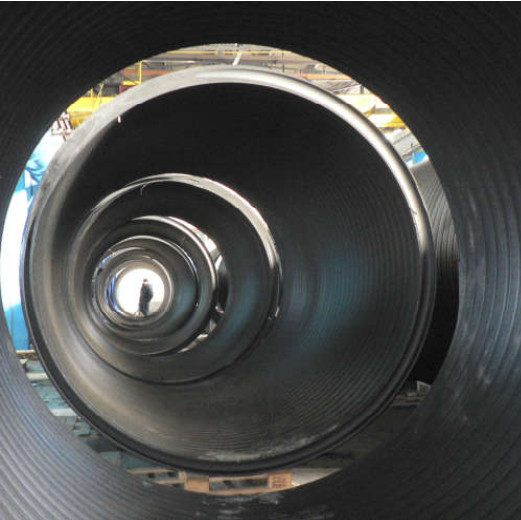

SPIRO-WEARTECH wear-resistant pipes

Spiroplast Plant has been a longstanding partner of WEARTECH in the European market. The company focuses on wear-resistant SPIRO-WEARTECH polypropylene pipes, which are primarily used as slurry conduits. These innovative pipes are designed to improve operational quality and extend the lifespan of slurry pipelines, even under conditions of intense abrasive wear.

Assistance and consultation from our experts!

Receive qualified assistance and consultation from our experts. We are ready to answer your questions, tell you about our services and solutions, and also help you make the right decision. Do not hesitate to contact us — we are here to help you!Spiroplast Plant has been a longstanding partner of WEARTECH in the European market. The company focuses on wear-resistant SPIRO-WEARTECH polypropylene pipes, which are primarily used as slurry conduits. These innovative pipes are designed to improve operational quality and extend the lifespan of slurry pipelines, even under conditions of intense abrasive wear. Additionally, they help reduce overall maintenance and replacement costs. The pipes are noted for their enhanced resistance to abrasive wear, are UV resistant, and are environmentally safe.

Spiroplast Plant officially commenced operations in 2008, and has since become a leader in manufacturing across Ukraine and abroad. The facility is equipped with modern production capacities that meet both national and international quality standards and requirements. Its products have gained wide recognition around the world due to their high quality and innovation. The latest extrusion technology installed at the plant enables automated production processes under the strict supervision of experienced specialists.

The primary materials used for pipe manufacturing are high-quality PE100 polyethylene and PP80 polypropylene. Spiroplast Plant stands out among other manufacturers for its exclusive products, including multi-layer SPIRO pipes and "Protect Crack Resist" pipes with enhanced crack resistance.

Furthermore, it is also worth mentioning the polypropylene products that contribute to the development of advanced water supply and sewage systems. The product range includes a wide assortment of polymer pipes of various diameters from 20 to 3000 mm for diverse systems: water supply, sewage, gas supply, heating supply, as well as wells and reservoirs for any taste and purpose.

The company's production strategy is focused on meeting the growing demand for high-quality plastic pipes and fittings in the domestic market, using polyethylene from the world's top brands such as Basell and Sabic.

Spiroplast Plant is committed to incorporating the latest scientific developments and technologies into production to ensure impeccable quality of our municipal systems.

The goal of Spiroplast Plant is to produce innovative, high-quality products to achieve and maintain a leading position among manufacturers of PP/PE pipes and their components.

SPIRO-WEARTECH WEAR RESISTANT PIPES

INSTALLATION

DESIGN

AUTHOR SUPERVISION

SANATION

The quality laboratory at Spiroplast Plant is equipped with unique technologies and equipment for thorough control of raw materials and finished products, ensuring compliance with all standards and requirements.

Quality control at each stage of production includes testing for strength and thermal resistance of products, as well as their ability to withstand the gradual formation of a network of cracks.

The laboratory has received a certification from the State Committee of Ukraine for Technical Regulation and Consumer Protection. The year 2007 was marked by the development and implementation of TU U 25.2-31149692-001:2007 specifications for polyethylene pipes. In 2009, Spiroplast Plant obtained the ISO 9001-2001 certification.

WHY WORTH CHOOSING WEARTECH

WE CHALLENGE WEAR & TEAR

OWN PRODUCTION

We produce lining materials

A WIDE RANGE OF PRODUCTS

Different materials - optimum solutions

SELECTION OF THE MOST EFFICIENT SOLUTIONS

Issues are solved on the basis of the best feasibility study

TAILOR-MADE EQUIPMENT

Contact us - we won't let you down

SOLVING NON-STANDARD COMPLEX TASKS

Solving unsolvable tasks is our daily routine!

INDIVIDUAL APPROACH

Our clients become our friends