FRP Reinforcement Systems and Ultra Ceramik, Ultra Mix SVS Linings.

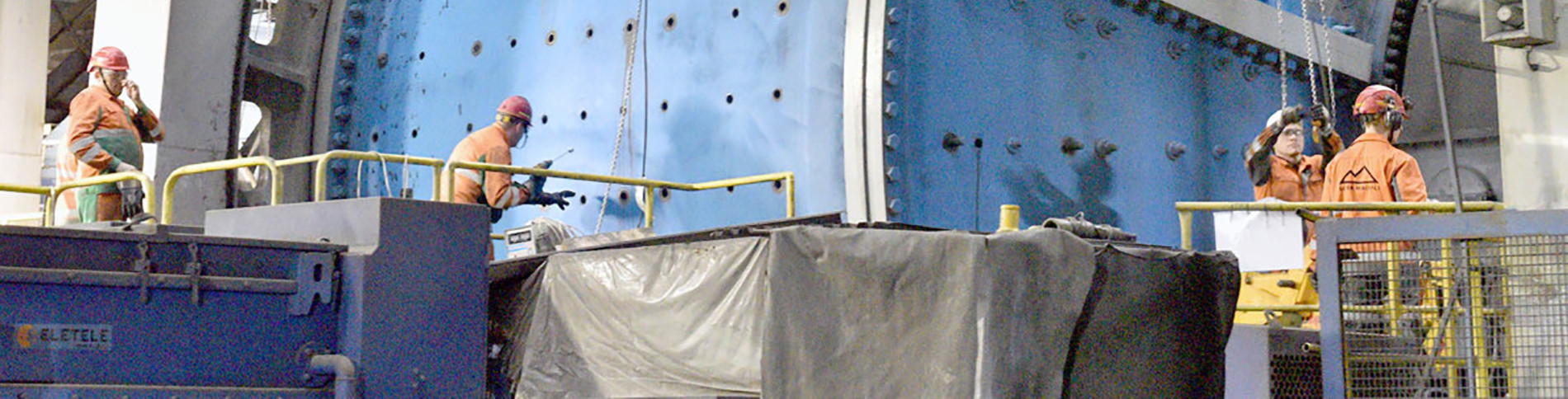

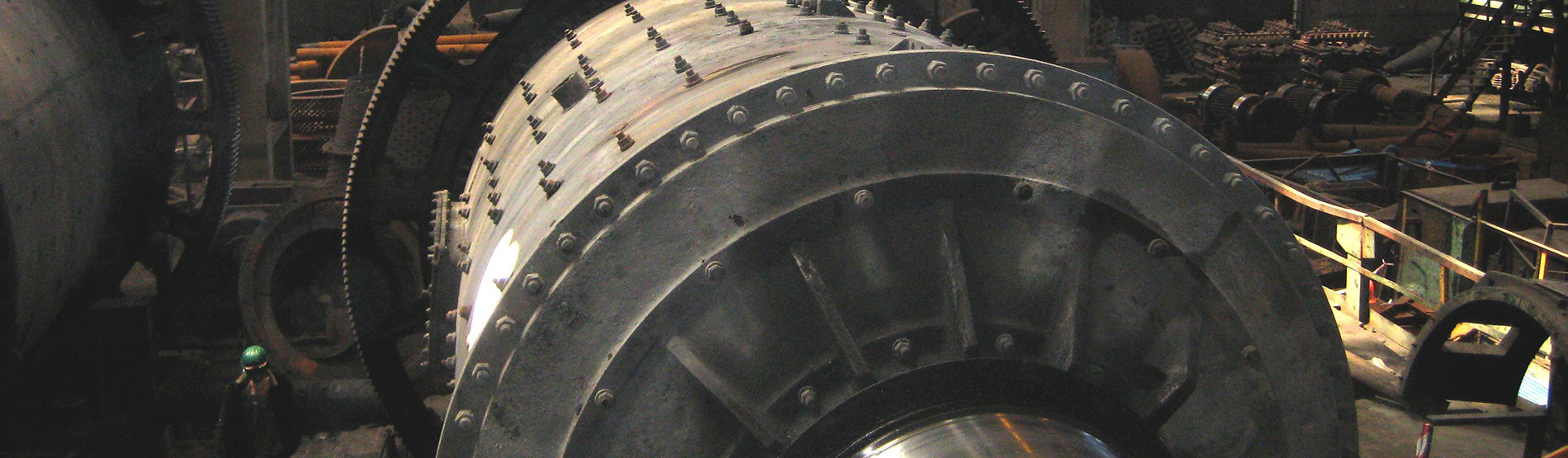

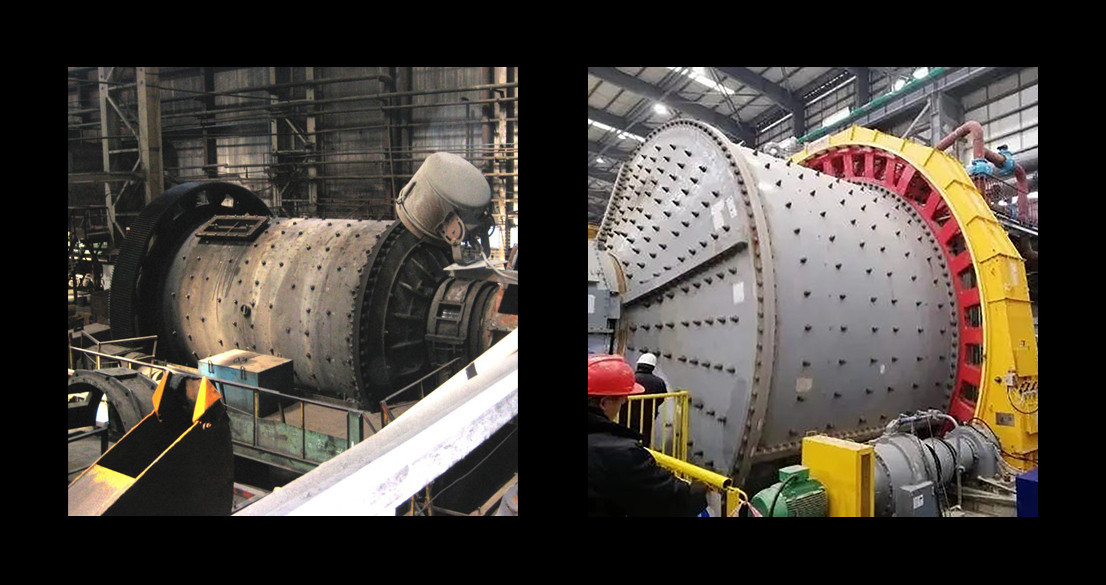

In modern operating conditions of ball mills, the importance of protecting and restoring their shells is becoming increasingly significant. Weartech offers innovative solutions for strengthening and protecting mill shells, which ensures durability and reliability of the equipment. The use of advanced technologies significantly reduces repair and maintenance costs, as well as extends the service life of the mills.

FRP System Reinforcement System

FRP System by Weartech is designed for structural reinforcement of metal mill structures. The system includes special composite materials with high tensile strength and elongation. Due to high adhesion, the system works as a monolith with the reinforced structure, eliminating the possibility of delamination.

The main component of the system is Mapewrap C Uni-AX carbon fiber, which has a tensile strength of at least 4850 N/mm² and a modulus of elasticity of at least 230,000 N/mm². Laboratory tests have proven that a single layer of carbon fiber with a thickness of 0.333 mm significantly increases the strength of the structure, reducing the maximum deflection under load to 3.97 mm.

Main Components of the FRP System

- Weartech Primer 1 high-adhesion primer for polymer systems.

- High-strength mastic for protecting carbon fiber in two layers.

- Medium-viscosity epoxy adhesive for bonding carbon fiber.

- Epoxy adhesive impregnation of carbon fiber to provide strength and hardness to the system.

- Coating the reinforced system with high-strength mastic to protect the fiber.

Advantages of the FRP System

The use of Weartech's FRP System significantly increases the tensile load-bearing capacity. A single layer of the system up to 3 mm thick increases the strength by 48-50%. The system is resistant to defects like delamination under increased mechanical loads.

An important advantage is the ability to perform repair work without hot methods, which significantly reduces equipment downtime and repair costs. All operations are performed manually, allowing standard personnel to carry out the work without additional training.

Ultra Ceramik Lining System

Ultra Ceramik by Weartech includes plates made from zirconium and aluminum oxides, which have high resistance to abrasive, corrosive, and chemical effects. The plate size is 20x20 mm, and the thickness varies from 4 mm, which allows even distribution of dynamic and impact loads, reducing the risk of system damage.

The plates are fastened using a special thixotropic adhesive mixture, providing high adhesion to polymers and a monolithic lining coating. Such a system reliably protects mills from exposure to aggressive environments and mechanical damage.

Ultra Mix SVS Lining System

Ultra Mix SVS by Weartech is made of ultra-high molecular weight copolymer, which provides resistance to high impact and vibrational loads due to the plasticity and damping properties of the coating. The system includes high-adhesion adhesive mixtures and mechanical fastening with standard bolts.

The feature of the system lies in the multi-component casting that creates a 3D molecular lattice, which ensures resistance to high mechanical loads, significantly increases the service life of the lining, and reduces the need for frequent repairs and replacements.

Advantages of reinforcement and lining systems:

- Repairs can be carried out in the shortest possible time without hot methods, saving costs and reducing equipment downtime.

- Strengthening and protecting the shell increases the service life compared to traditional repair methods with overlay welding.

- Simple work execution allows the work to be performed by regular personnel without additional training.

Specification Table

| Reinforcement | Elastic Modulus [GPa] |

Thickness [mm] |

Width [mm] |

Cross-sectional Area [mm²] |

Tensile Strength [N/mm²] | Tensile Load [KN] |

| A500 | 210 | 14 | 154 | 500 | 76.97 | |

| A600 | 210 | 14 | 154 | 600 | 92.36 | |

| A500 | 210 | 16 | 201 | 500 | 100.53 | |

| Mapewrap C Uni-AX 300 | 252 | 0.333 | 100 | 33.3 | 4900 | 163.17 |

| Mapewrap C Uni-AX 600 | 252 | 0.666 | 100 | 66.6 | 4900 | 326.34 |

| Mapewrap C Uni-AX 300 HM | 390 | 0.333 | 100 | 33.3 | 4100 | 136.34 |

| Mapewrap C Uni-AX 600 HM | 390 | 0.666 | 100 | 66.6 | 4100 | 329.60 |

Weartech provides reliable protection and reinforcement of mill shells, offering innovative FRP System and Ultra Ceramik and Ultra Mix SVS linings. These solutions significantly extend the service life of the equipment and enhance its reliability. Weartech is your reliable partner in equipment protection and restoration.