Repair and restoration of gas ducts

The repair and restoration of the structural integrity of coke gas ducts is a key step in maintaining the efficiency and safety of equipment operation. This project will outline the primary stages and approaches to performing such work.

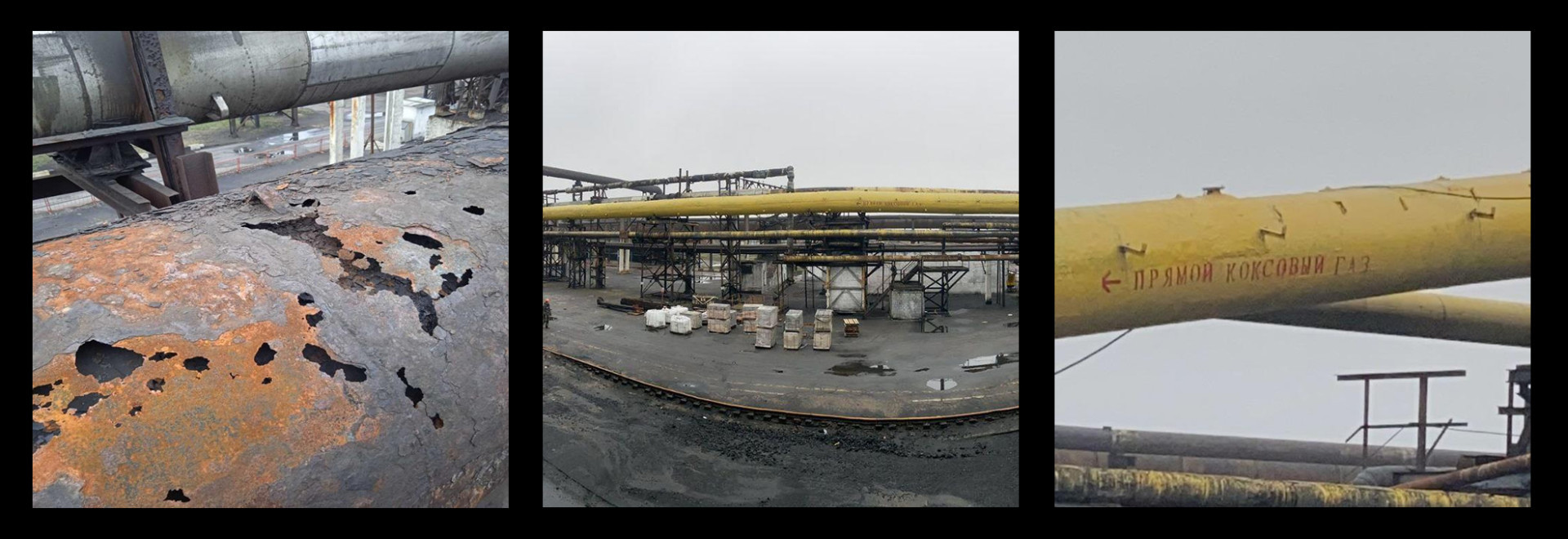

Condition of the Gas Duct Before Starting Work

At the start of the work, the gas duct was contaminated and exhibited damage that required immediate intervention. The main issues included accumulations of resin and other contaminants, as well as the presence of leaks and cracks.

Base Preparation

Mechanical cleaning of the gas duct base is performed using metal brushes to remove resins and contaminants. Additionally, a specialized chemical cleaner is applied, allowing for chemical cleaning and dust removal while eliminating spark formation. This method ensures optimal adhesion of the gas duct’s existing structure.

Leak Sealing

Leaks are sealed using a chemical anchor that sets within minutes. With high adhesion and specially selected chemical compositions, complete airtightness is achieved, along with a high compressive strength of up to 100 N/mm².

This stage is crucial to ensure airtightness, restore the original geometry of the gas duct, and increase its resistance to tensile loads. Modern materials allow for continuous equipment operation and eliminate the need for hot work.

Priming and Application of Leveling Compound

After cleaning and sealing leaks, a primer is applied to ensure reliable adhesion. A chemically resistant and wear-resistant leveling compound is then used, which provides the system with rigidity and strength after full curing.

Application of Carbon Fiber Fabric

The key stage involves attaching bidirectional carbon fiber fabric, which has high tensile and compressive strength, ensuring system resistance to pressure and vacuum during equipment operation.

The use of modern materials and technologies significantly improves the efficiency and safety of gas duct repairs, ensuring the longevity and reliability of the system.

System Advantages

- Ensures airtightness of the repaired area

- Restores the original geometry of the gas duct

- Increases tensile strength

- Maintains structural mass and load capacity

- Continuous work execution without the need for hot methods