Coal beneficiation plants

Reducing equipment wear at a coal beneficiation plant is an important task for the company, and a whole range of measures is aimed at its solution, including the installation of protective coatings on various equipment units.

The lining can be made from various materials, including overlay welding, high-alumina ceramics, basalt casting, etc. Protective materials are installed on parts of the equipment that are most susceptible to impact, abrasive, cavitation, chemical and other types of wear, for example, on blades, augers, grates, hopper walls, etc.

The advantage of protective coatings is that they can be installed on existing equipment without having to completely replace it. In addition, protective coatings can be produced individually for each piece of equipment, which provides an optimal balance between the cost of the coating and its protective properties.

1. Overlay welding lining is an effective technology for protecting equipment of coal preparation plants from wear and tear. Examples of equipment and sites where bimetal is commonly used in coal preparation plants include:

- Sorting equipment. Sorting equipment is used to separate coal particles by size. These components are subject to intense abrasive wear. Overlay welding can effectively resist the wear and tear of the screening equipment and thereby extend its service life.

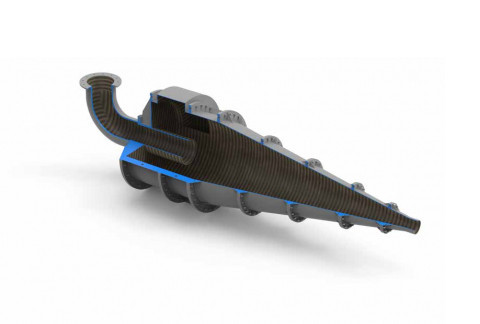

- Cyclones. Cyclones are used to separate coal particles from the air stream. These components are subject to high levels of abrasion and can wear out. Overlay welding can be used to protect cyclones from wear and extend their service life.

- Feeders. Feeders are used to transport coal from one production area to another. These components are subject to high levels of abrasion and can wear out. Bimetal can be used to protect feeders from wear and increase their service life.

- Pipes and chutes. Pipes and chutes are used to transport coal and other materials during the beneficiation process. These components are subject to high levels of abrasion and can wear out. Overlay welding lining is used to protect pipes and gutters from wear and increase their service life.

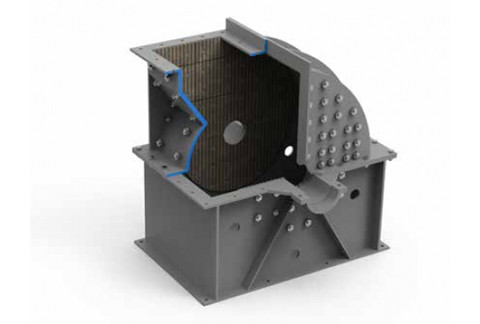

- Crushers. Some components and parts of crushers in the process of grinding coal particles are subjected to intense abrasive and impact wear and require replacement. Overlay welding can be effectively used to protect crushers from wear and increase their service life.

|

|

|

2. Cast Basalt. Cast basalt lining can be effectively used to protect process equipment at coal preparation plants. Among the critical types of equipment and components in coal preparation plants that are subject to high wear and can benefit from cast basalt linings are:

- Trays and hoppers. Trays and hoppers are important components of coal preparation plants where coal goes through various stages of processing. They are subject to heavy wear due to the abrasive nature of the coal and the impact of falling material. The use of cast basalt lining for chutes and hoppers can significantly reduce wear and increase equipment life.

- Cyclones. Cyclones are commonly used to separate coal and ash particles. They are exposed to abrasive coal particles and require wear resistant solutions. Cast basalt liners can be used on the internal surfaces of cyclones to protect against abrasion and increase their durability.

- Pipelines and chutes. Pipes and chutes are responsible for transporting coal pulp or water in coal preparation plants. These components are subject to wear and erosion due to abrasive coal slurry. Applying a cast basalt lining to the inner surfaces of pipes and gutters can significantly increase wear resistance, reducing maintenance and downtime.

- Screens and vibrating feeders. Screens and vibrating feeders are used to separate and transport coal particles of various fractions. The constant movement and impact of coal can wear the surfaces of these components. Cast basalt liners can be used to protect screens and vibratory feeders, minimizing wear and extending their life.

The choice of protective coating must take into account the operating conditions of the equipment, as well as the characteristics of the abrasive materials that pass through the equipment. For example, ceramic coatings may be more effective with low density particles, while bimetal carbide linings may be preferable with larger, heavier particles.

3. High-alumina ceramics are also widely used for wear protection of critical process equipment in coal preparation plants. Here are just a few examples of the use of high-alumina ceramics for equipment protection:

- Cyclones. Cyclones are commonly used in coal preparation plants to separate coal particles from ambient air or water. Due to the abrasive nature of coal, cyclones can be subject to significant wear. High-alumina ceramics can be used as liners or wear-resistant coatings on the interior surfaces of cyclones to resist abrasion and extend their life.

- Dense media separators. Dense media separators, also known as heavy media cyclones, are used to separate coal based on its density. These separators often wear out due to the movement of dense media and coal particles. High-alumina ceramics can be used to line the internal surfaces of dense media separators, providing exceptional wear resistance and extended service life.

- Conveyors and transfer points. Conveyors and transfer stations play a critical role in coal preparation plants as they transport coal through all stages of processing. These components are subject to constant abrasion and impact. High-alumina ceramics can be used as liners or wear plates in conveyor chutes, transfer points and other high wear areas to minimize wear, prevent material leakage and ensure efficient material flow.

- Screens and sieves. Screens and screens are used to separate coal particles into different sizes. Constant vibration and abrasive contact with coal can cause significant wear. High-alumina ceramics can be used as a wear resistant lining for screens and screens, reducing wear and extending screen life resulting in improved screening efficiency.

- Crushing equipment. Pulverizers, including ball mills and vertical roller mills, are often used in coal preparation plants to reduce the size of coal particles. During the grinding process, these mills are subjected to high levels of abrasive wear. High-alumina ceramics can be used as linings or protective coatings inside mills to increase wear resistance and minimize maintenance and repair work on this type of equipment.

When using lining, it is also necessary to take into account the maintenance process of the equipment and the availability of its parts for repair. For example, coatings that need to be changed too often or are difficult to install may be less effective than coatings that last longer and have easily accessible parts.

Furthermore, when choosing a specific type of lining material, it is necessary to take into account its influence on the coal processing process, since some coatings can change the surface characteristics of the equipment and thereby affect the coal processing itseld.

In general, given the operating conditions of the equipment in a particular coal preparation plant, the use of different types of lining can be one of the most effective methods of overall reducing wear and increasing equipment productivity.