Thermovacuum Fixation of Ceramic Lining

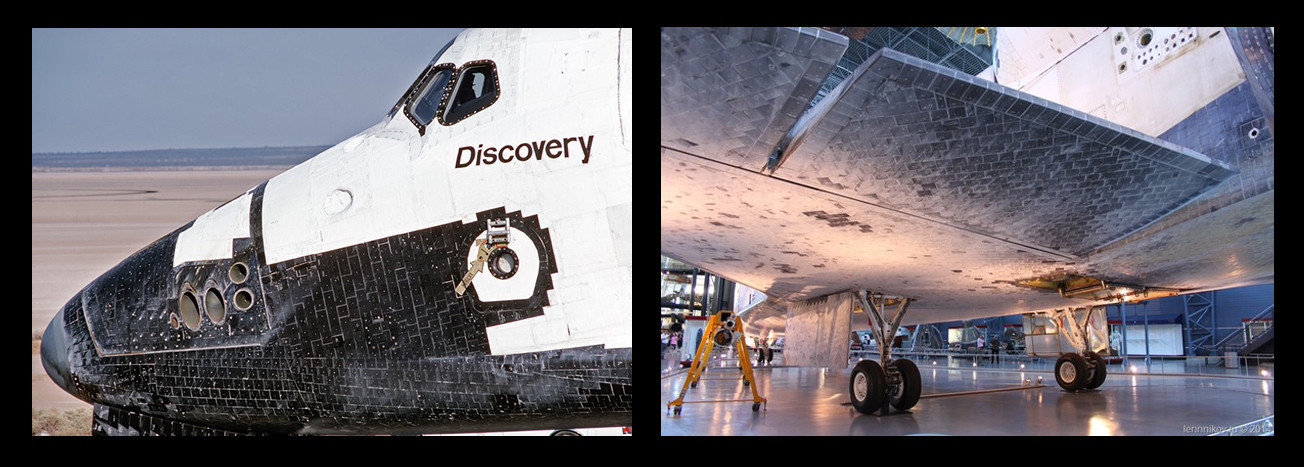

The reusable space shuttle "Discovery" made 39 trips to space over 27 years of service. During each launch, the spacecraft's outer shell, made of the strongest ceramic tiles, bore the main load. Each tile had its own identification number and was fixed with a special heat-resistant adhesive capable of withstanding colossal pull-off loads of up to 112 MPa.

Technologists from "WEARTECH", in collaboration with the Ukrainian company "Termolit-Invest", have developed a thermovacuum fixation system for wear-resistant shaped lining elements based on zirconium oxide, aluminum oxide, silicon carbides, and other types of ceramics to protect industrial equipment from various types of wear, achieving a pull-off strength of at least 115 MPa.

Thermovacuum fixation technology has proven to be an extremely effective process that ensures stable performance regardless of the base material, be it steel, cast iron, or other mineral and non-mineral bases. This technology effectively protects the working blades of mill fans, exhauster volutes, working wheels of dredger and earth pumps, as well as similar industrial equipment using small-segment shaped ceramic linings.

After the bonding and thermal treatment processes according to this technology, the equipment and lining are ready for operation in the shortest possible time without losing strength characteristics.

The use of vacuum in the fixation procedure for small-segment ceramic linings with adhesive is particularly important and serves several key purposes:

- The vacuum helps to remove air from under the ceramic segments and the adhesive layer. This is crucial because air bubbles can reduce the adhesive's bonding properties and weaken the connection between the segments and the surface.

- The vacuum ensures uniform pressure across the entire surface of the ceramic segments. This promotes even adhesive distribution and ensures tight contact between segments and the surface, preventing displacement or gaps.

- Under vacuum conditions, the adhesive penetrates microcracks and pores on both the equipment surface and the backside of the ceramic segments. This improves adhesion and enhances the fixation strength.

- In some cases, vacuum accelerates and ensures more uniform adhesive polymerization, especially when using heat-resistant adhesives. This speeds up the fixation process and improves its efficiency.

- The vacuum process eliminates the influence of external factors such as moisture and oxygen, which can negatively affect adhesive polymerization and lead to deformation of the ceramic segments.

In summary, the successful execution of the thermovacuum fixation procedure for small-segment ceramic linings requires meticulous preparation, careful material selection, condition control, and adherence to all technological recommendations. It is essential to pay attention to each stage of the process to ensure the durability and reliability of the ceramic lining fixation on industrial equipment.

Experts from "Termolit-Invest" possess the necessary knowledge, extensive practical experience, and are ready to perform thermovacuum ceramic lining fixation to protect your industrial equipment.